High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

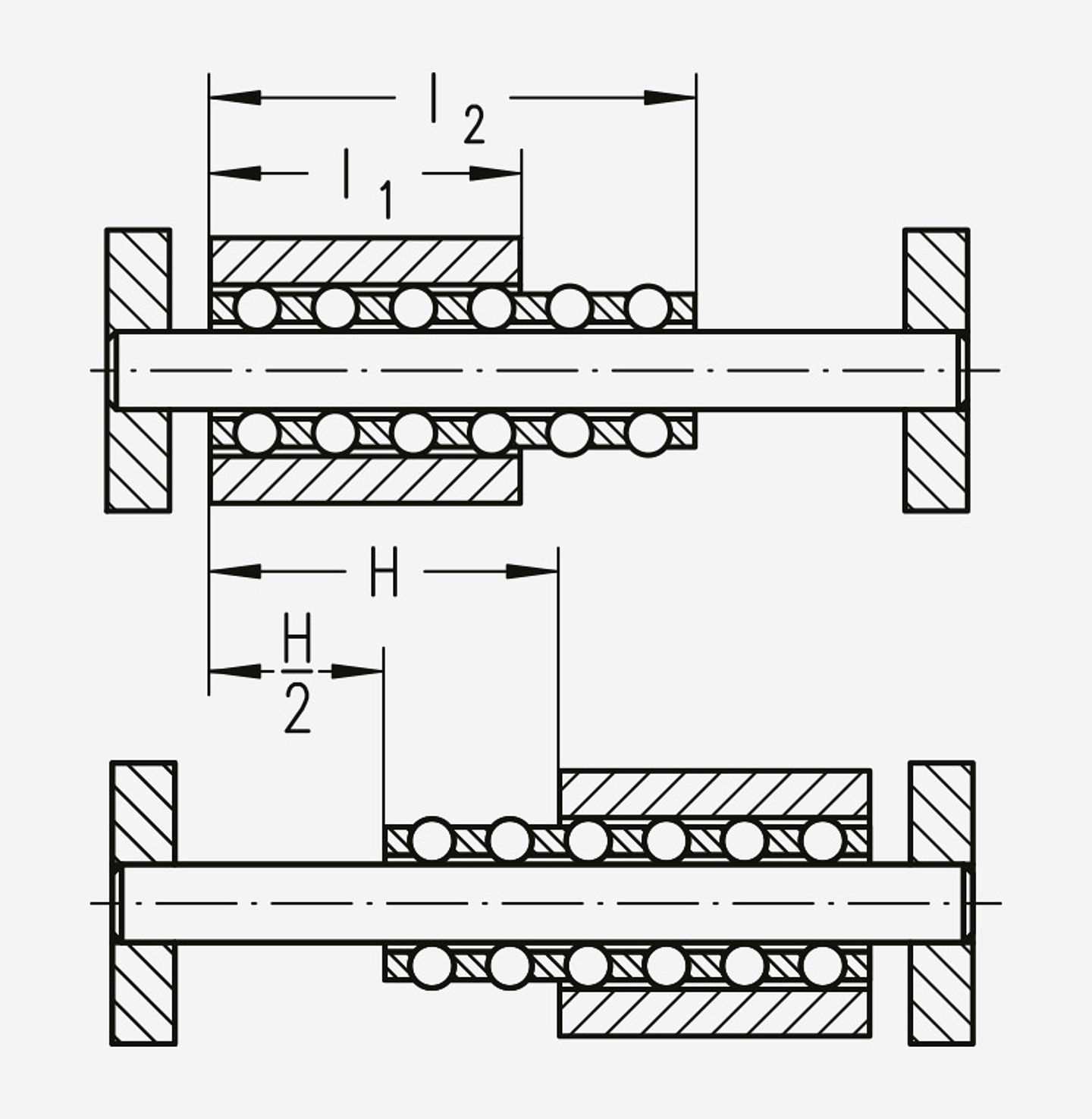

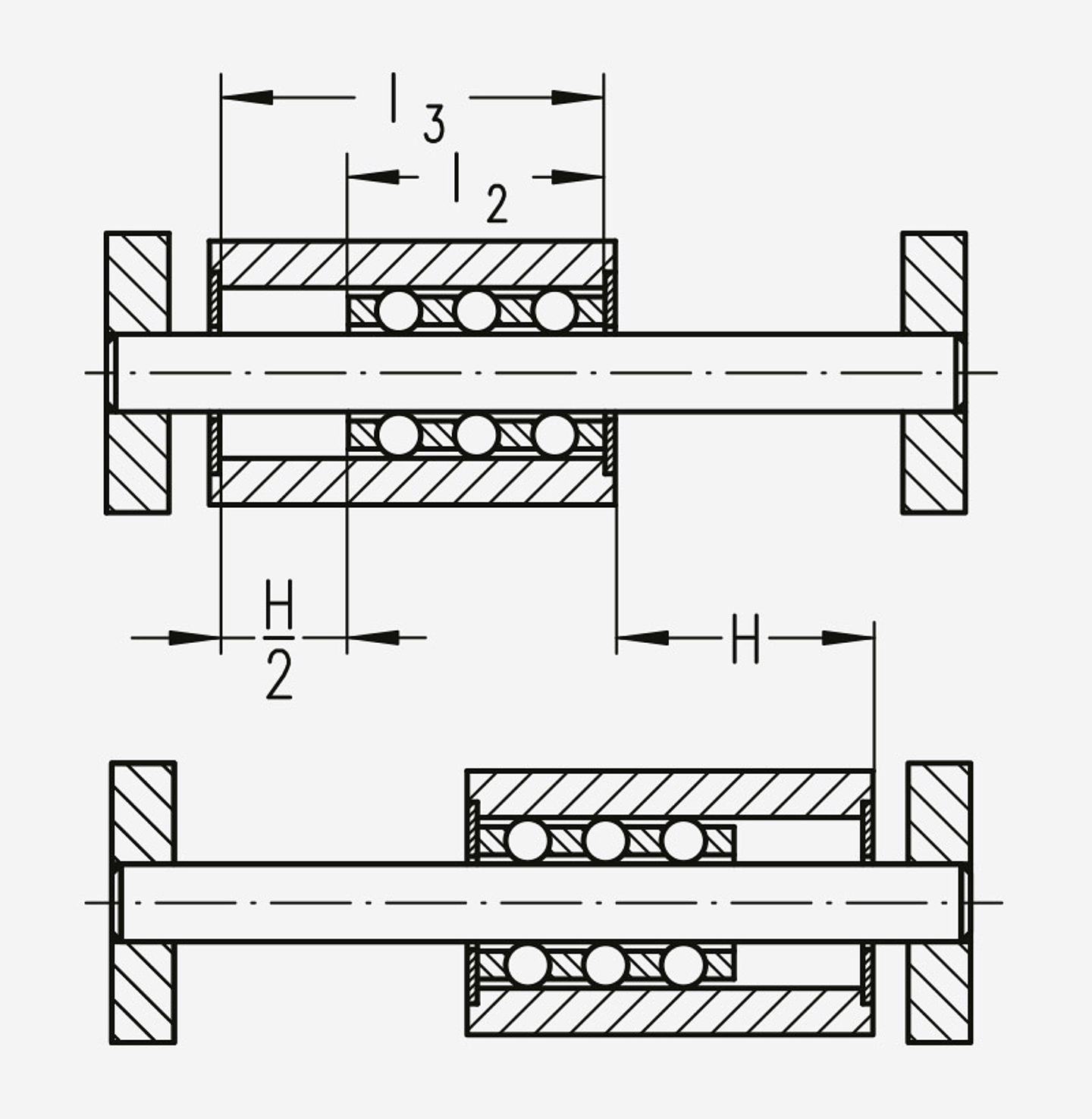

Length of stroke and contact length

The contact length is determined by the position of the guide bush, ball cage and guide shaft towards each other in the end positions of the linear movement. There are two different modes of operation.

Open guide bush<br/> Cage length L2 can be longer than or equal to guide bush length L1.<br/> Max. linear movement: H = 2 (L2 – L1)

Closed guide bush<br/> Bushing length L3 is longer than cage length L2, the ball cage remains within the guide bush.<br/> Max. linear movement: H = 2 (L3 – L2)

For both modes of operation, the aim is to achieve a constant contact length E over the entire linear movement. This is always the case with closed rotary stroke bearings. With open rotary stroke bearings, the bushing should be flush with the cage in the end positions of the linear motion. If the bushing extends beyond the end of the cage, the contact length and thus the loading capacity of the rotary stroke bearing is reduced in this position.

The shortest permissible ball contact length E is determined by the required loading capacity. The load ratings of the ball cages can be used as guide values.

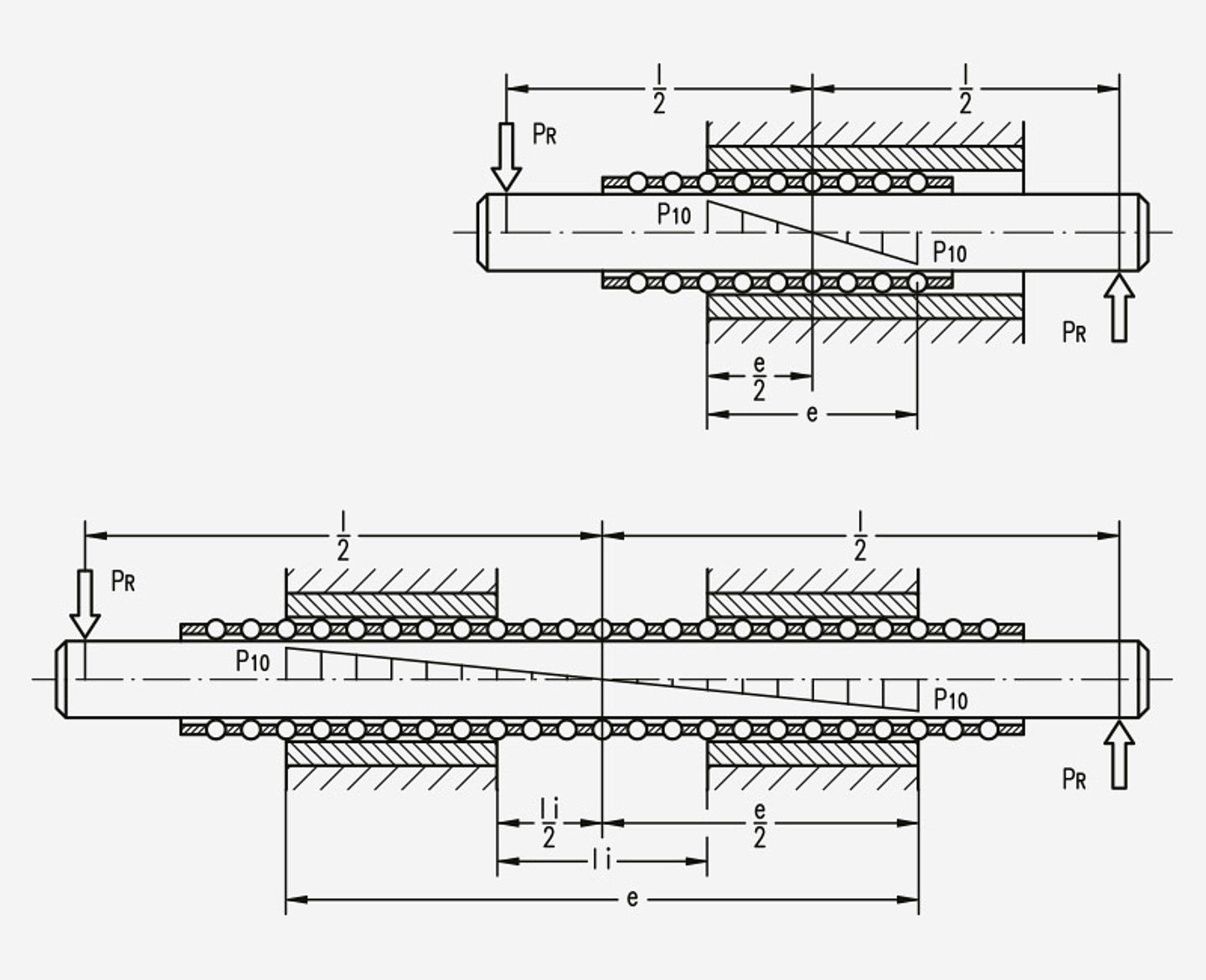

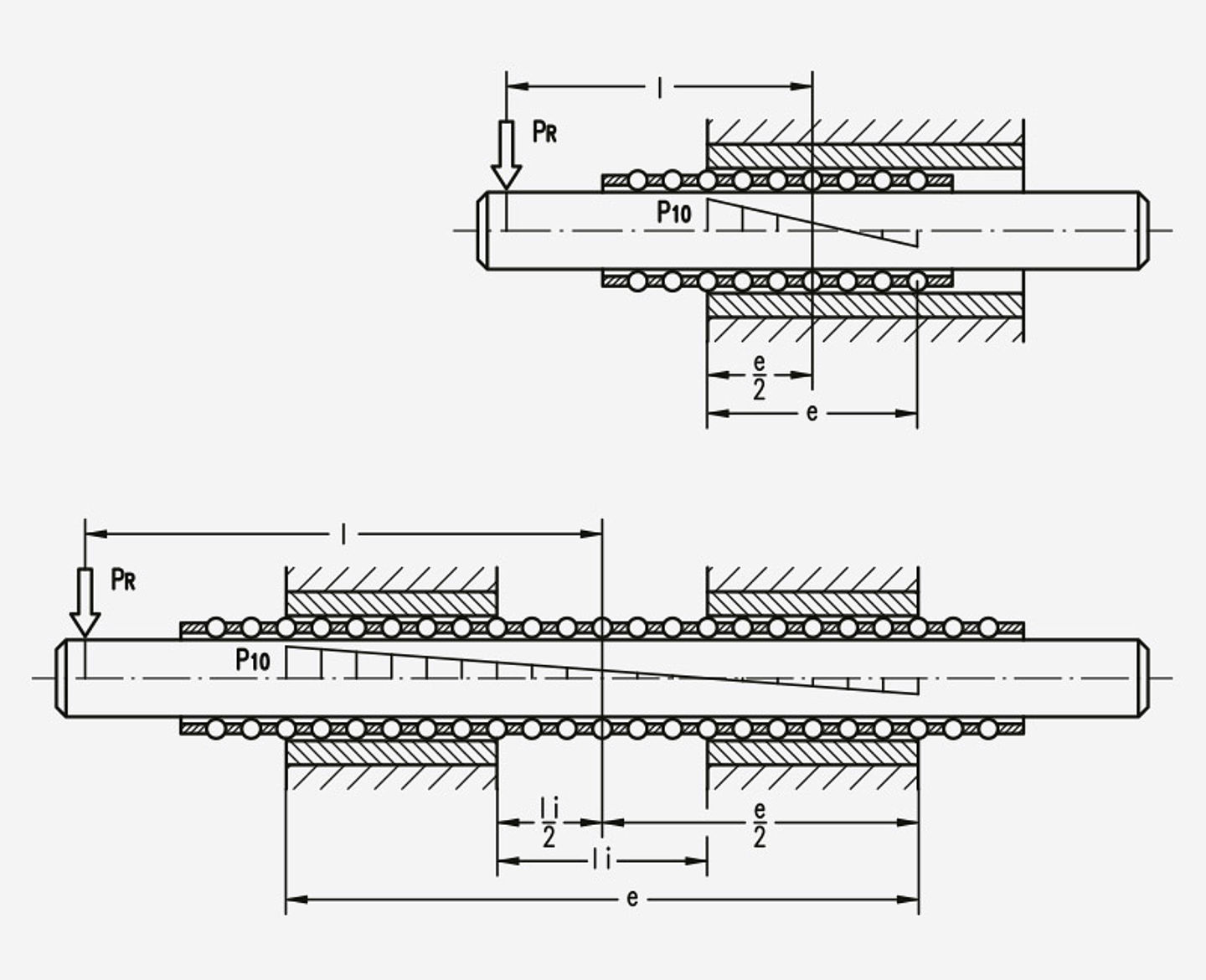

Reference contact length e

To calculate a rotary stroke bearing, it is always necessary to determine the reference contact length e = ball contact length in the case of unfavorable load distribution.

At a low load

For rotary stroke bearings used for precise guidance without a significant load, the following values E are recommended depending on dw: see table.