High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

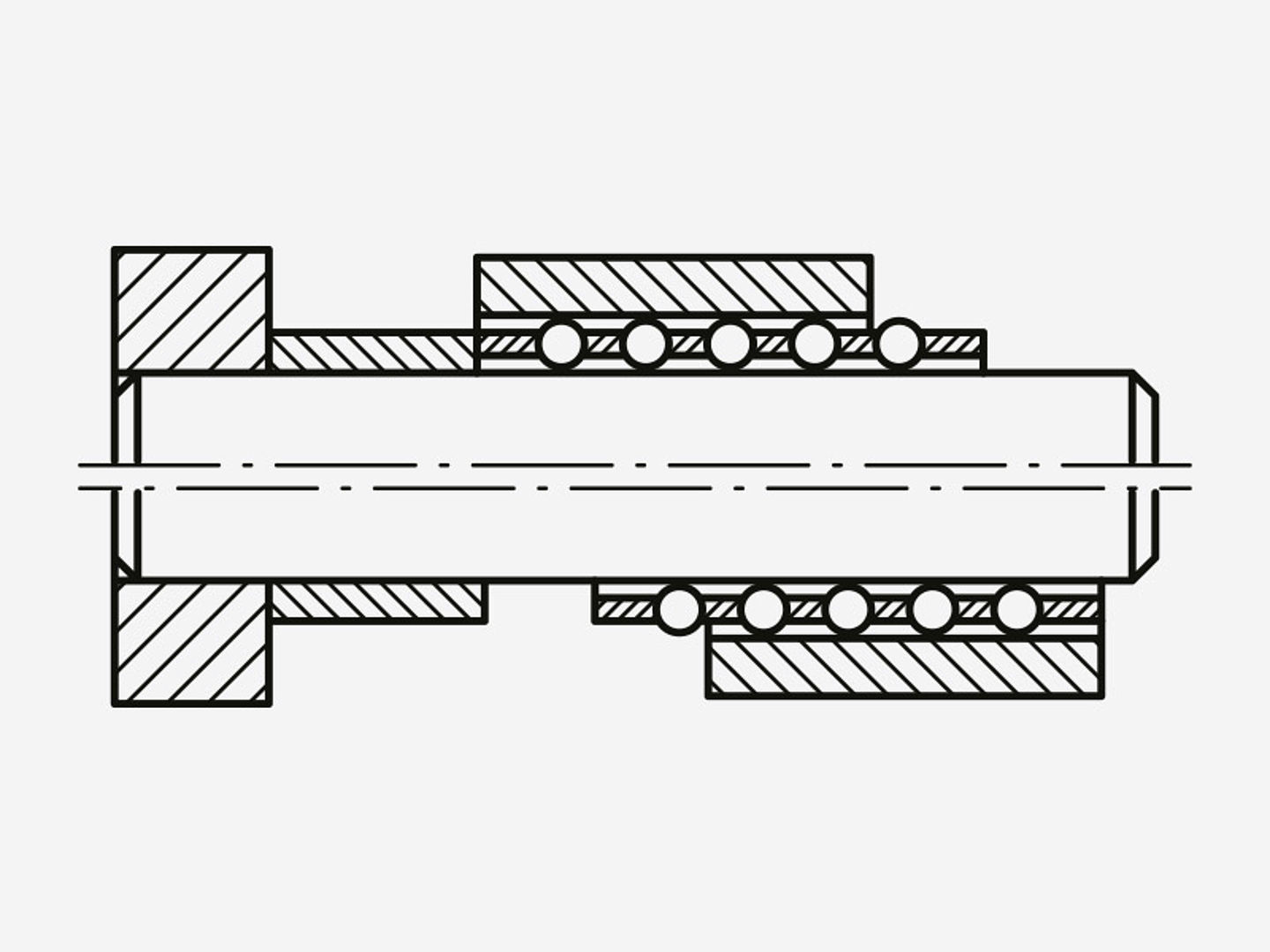

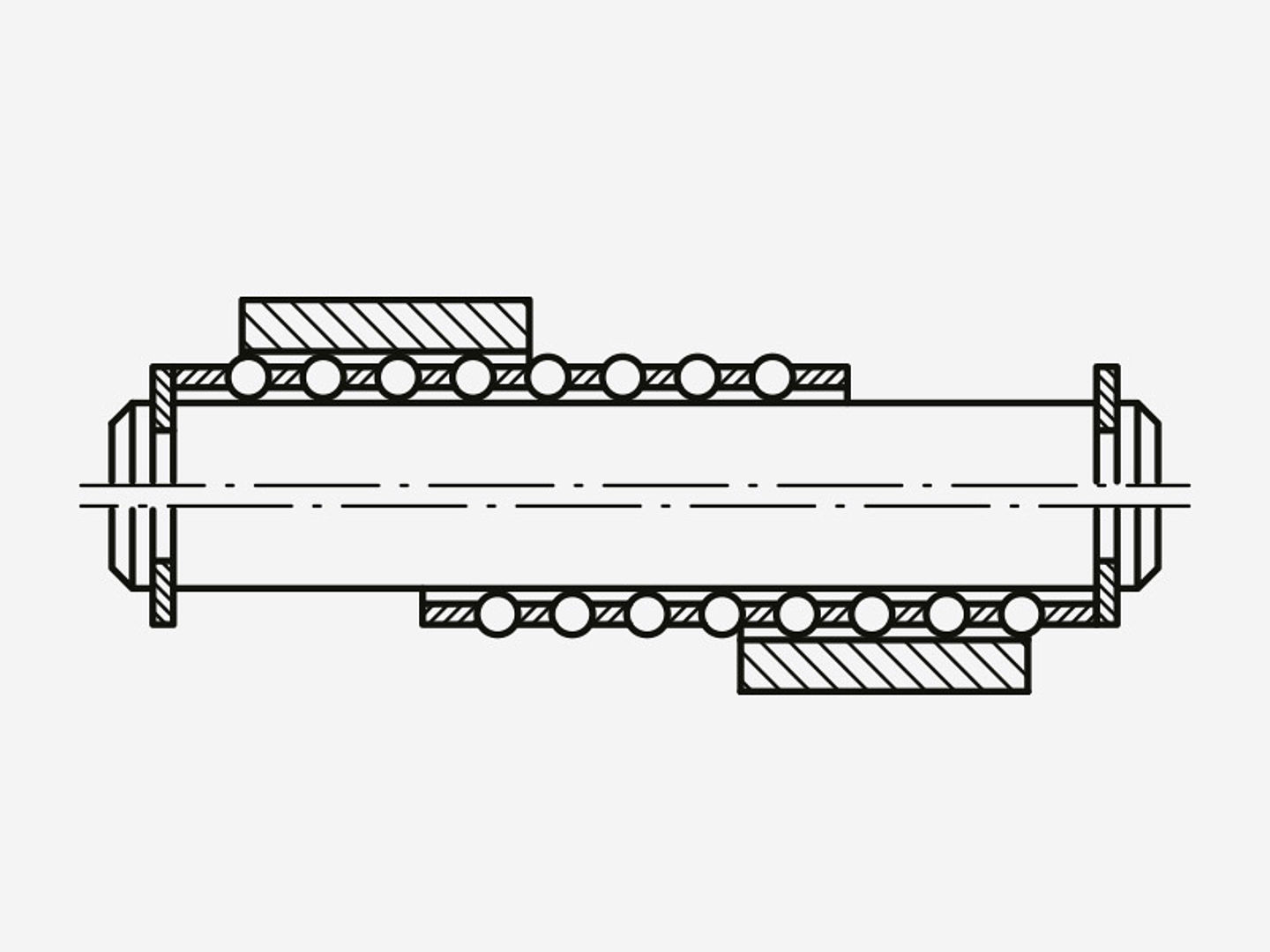

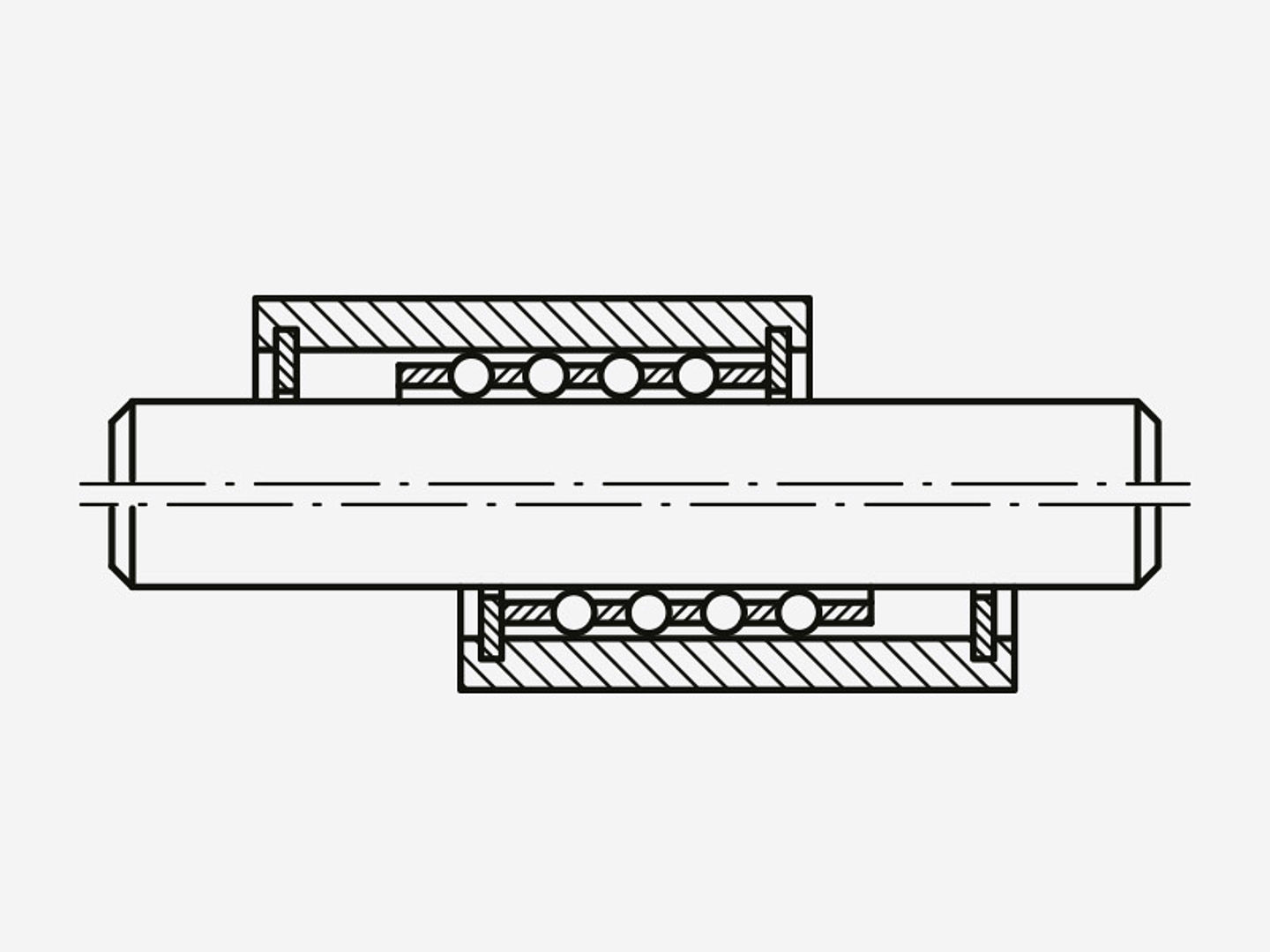

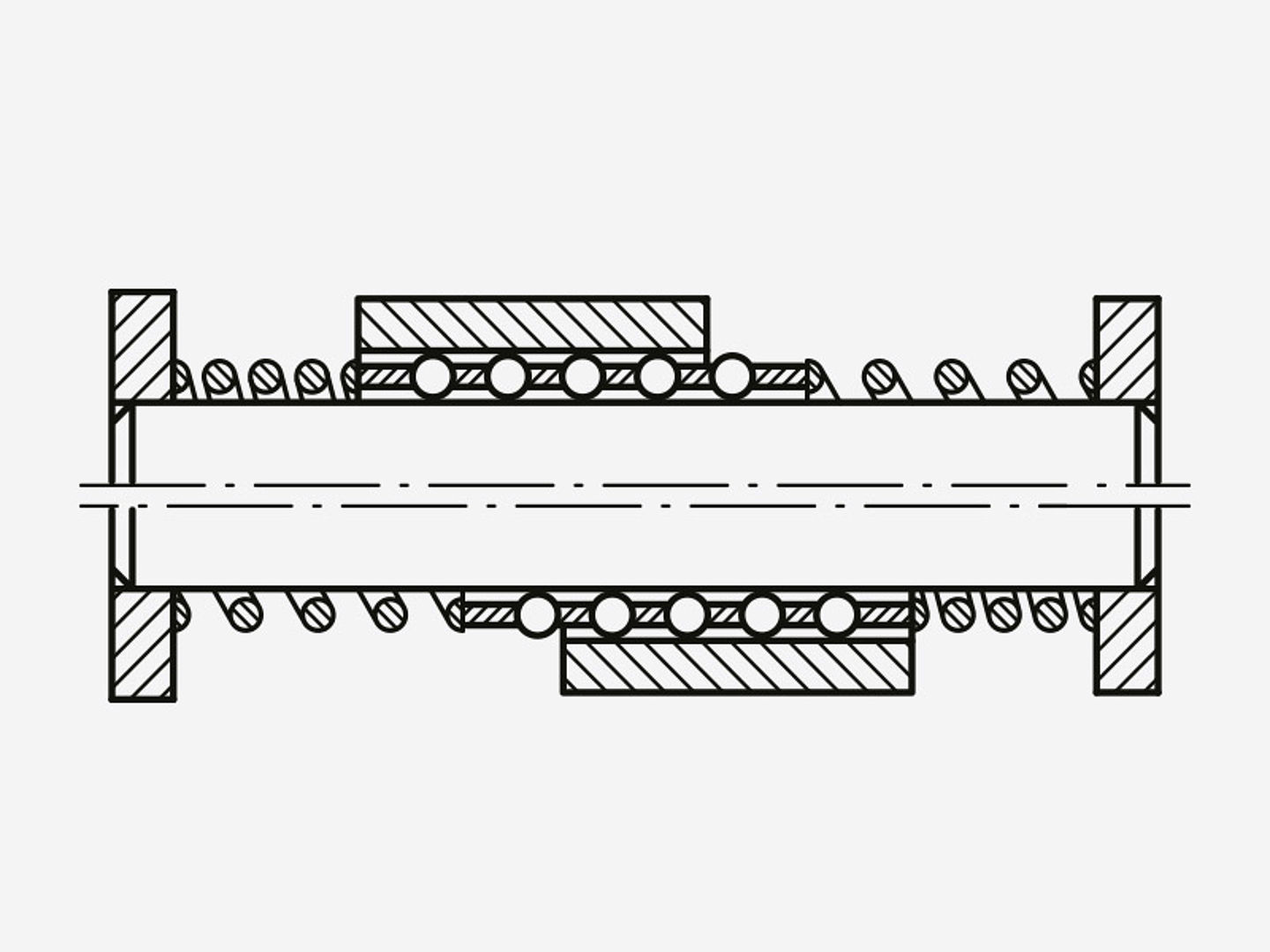

Installation of the ball cage

If ball cages are installed with open guide bushes, the ball cage should enter the guide bush together with the guide shaft. As the balls are under interference fit (preload), this is the only way that prevents the balls from sliding between the bush and shaft.

For rotary stroke bearing assemblies with closed guide bushes, the guide shaft must be inserted against the resistance of the preload. This does not damage the rotary stroke bearing. Grease lubrication is useful to prevent damaging the balls.

On ball cages with a larger diameter, particular care must be taken to ensure that the cage is sufficiently centered in the guide bush during assembly.

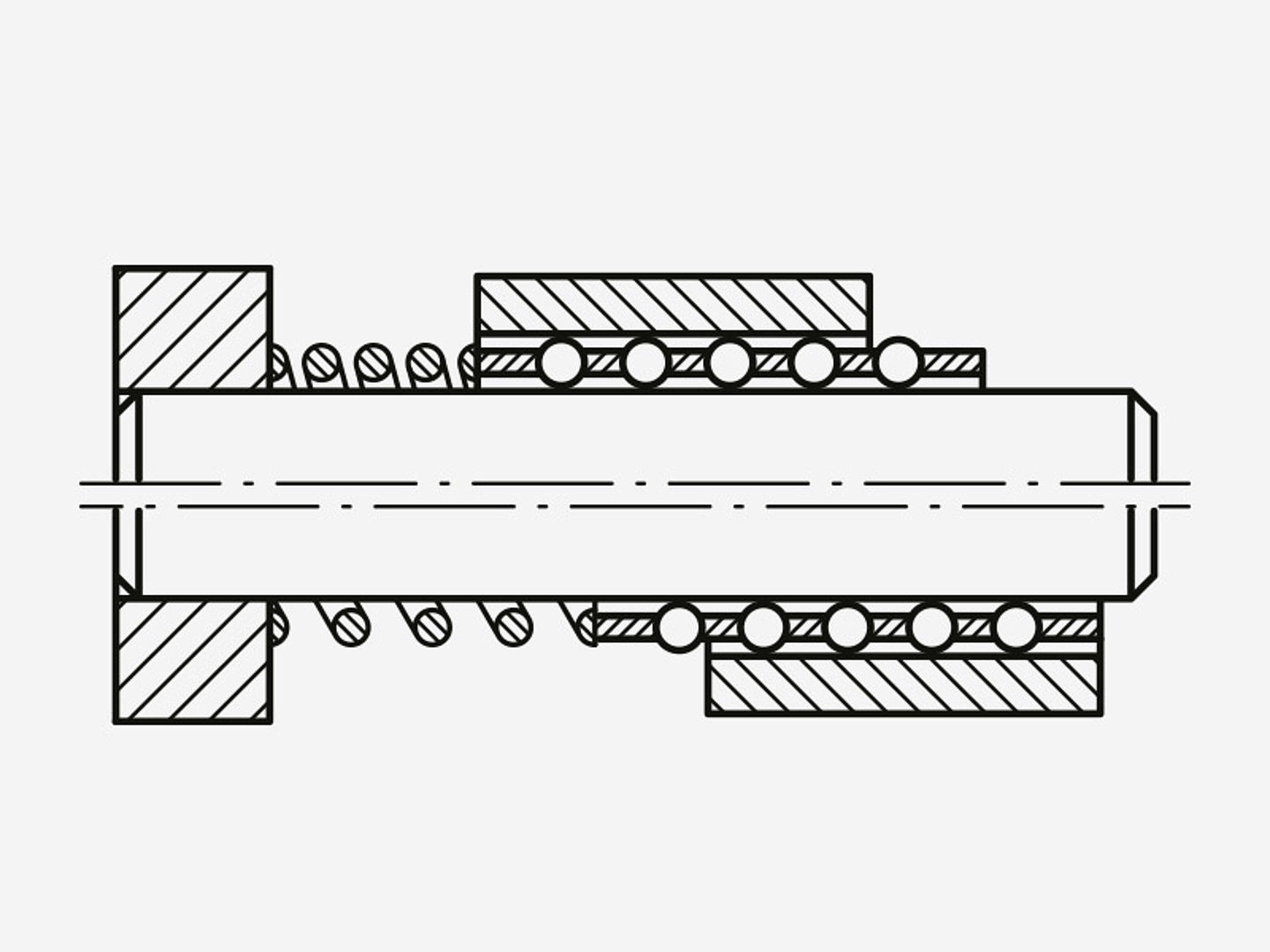

Travel limitation for the ball cage

Despite the frictional connection between the balls and the running surfaces, the ball cage can change its position in the longitudinal direction ("wandering cage").

In rotary stroke bearings with an open guide bush, the cage travel must be limited so that the ball cage cannot move out of the guide bush more than a certain permissible distance. This is ensured by fixed or elastic stops.

- Stop sleeve that is installed loosely over the shaft between the ball cage at the stroke reversal position and the part that is retaining the shaft.

- Clamping bush that can be fixed at any position on the shaft.

- Circlips that limit the cage travel.

- Compression springs.