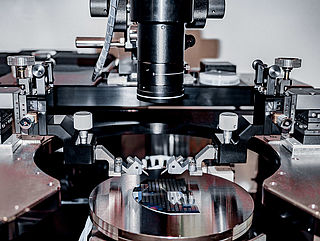

Installation, operation and maintenance

A rotary stroke bearing consists of the following components: guide bush, ball cage and guide shaft. The catalog range of MarMotion rotary stroke bearings offers you a wide range of options from which you can choose the combination that suits your application.

Components with the same dw (shaft diameter) and d1 (inner diameter of the guide bush) can be combined. If the bushings are closed with stop rings or sealing rings, the ball cage must not be longer than the guide bush (L2 ≤ L3). All of the components can also be manufactured according to your drawings. In addition, alternative materials and production processes are available, that, for example, enable dry running or the use in vacuum or cleanroom environments.

All of the components can be ordered individually. If you order guides bushes, ball cage and guide shafts together, you will receive the rotary stroke bearing assembled as a complete set. The great advantage of this is that a precisely defined preload is set at the factory. This is achieved by pairing the guide bush, balls and guide shaft. During this process, the individual components are selected and adapted in such a way that the combination provides the optimum interference fit (preload), which ensures a smooth movement free of backlash, but also good rigidity and a long service life. For that reason, the paired rotary stroke bearings should be installed in the assigned combination of guide bush, ball cage and guide shaft just as they are delivered by Mahr. Please consult Mahr for advice on determining of the optimal preload based on the calculation principles and practical experience.

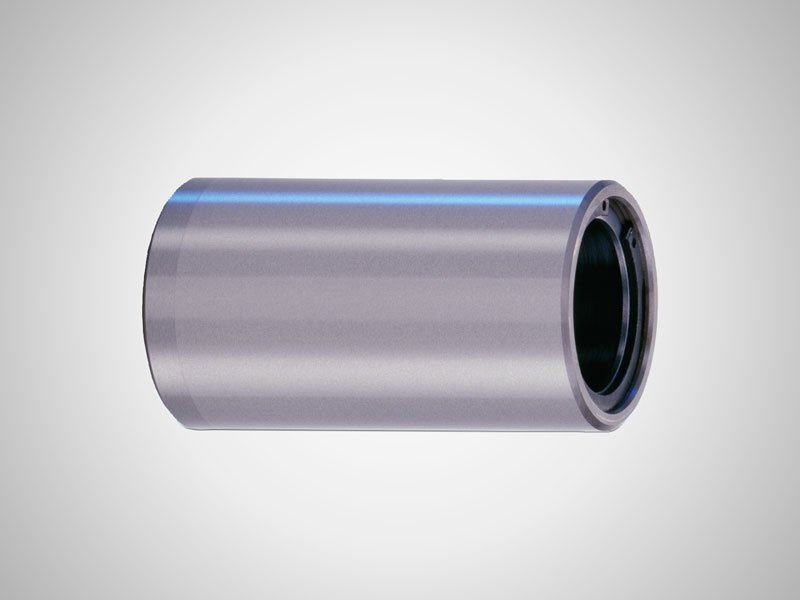

Guide bushes

The guide bushes are available as an open type or closed with wiper seals or sealing rings. The choice is made based on the length of the stroke path and the requirement for a travel limitation for the ball cage or a seal. The selected guide bush must at least be long enough to ensure a sufficient contact lenght during operation to achieve the required load rating and rigidity.

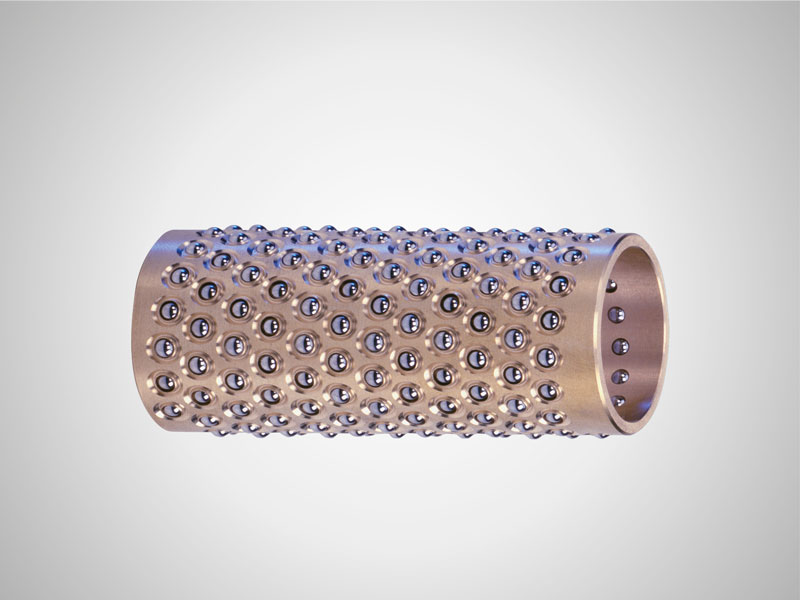

Ball cages

The catalog range includes ball cages made of brass or plastic (POM). All of the cages are equipped with high-precision balls according to DIN ISO 3290, grade 5. Ball cages made of brass are characterized by their low frictional behavior and long service life. Ball cages made of plastic reduce the moving masses due to their low weight and thus also enable higher accelerations. In addition, the cobinable plastic elements can also be used to make long ball cages which allow longer stroke paths easily and at low costs. The selection is made based on environmental conditions, the type of movement and, above all, the size of the forces and moments acting on the rotary stroke bearing. For this purpose, the maximum load ratings C that can be achieved by a ball cage are specified. Please ask Mahr for advice to select the ball cage based on the design calculation and practical experiences.

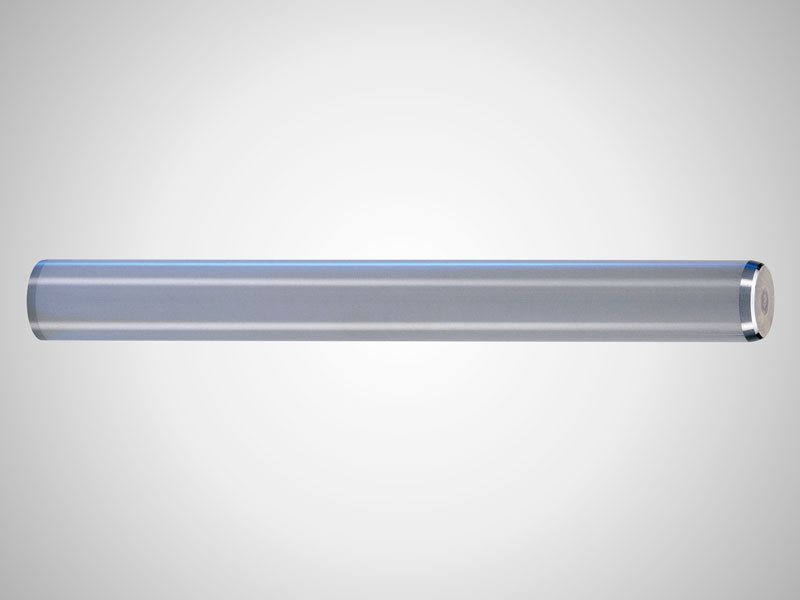

Guide shafts

The guide shafts, with their tight manufacturing tolerances, ensure that the preload can be adjusted accurately by pairing with the guide bushes. A precision machined surface minimizes friction and extends the service life of the ball-bearing guide.

The guide shafts included in the catalog range are also available with internal threads on the face side from a diameter of dw = 12 mm.

MarMotion rotary stroke bearings are delivered with anticorrosive agent. After removing the transport packaging, wash off the anticorrosion agent with a suitable cleaning agent. Depending on the operating conditions, oil or grease lubrication is then applied to the rotary stroke bearing.

Handle the rotary stroke bearings with care and keep it clean, as even small particles of dirt inside the rotary stroke bearing can cause subsequent damage.

When ordering complete sets of rotary stroke bearings consisting of a guide bush, ball cage and guide shaft, the components are paired with optimal preload at the factory. It must be ensured that the components are installed in the same unchanged combinations as they were delivered. Interchanging components may result in poor running properties or a shortened service life of the rotary stroke bearings.

In principle, the same specifications apply here as for ball bearings: Depending on the load, a thin film of lubricant will be sufficient for a long period of continuous operation. The Rolling bearing lubricants commonly used today – these are the only ones that should be used for a rotary stroke bearing – have all the properties which ensure fault-free operation.

Rolling bearing lubricants have a good consistency, are chemically neutral, non-resinous and free of abrasive substances. Lubricant additives must be selected according to the operating conditions (temperature, pressure, speed, corrosion behavior, etc.). Greases and oils generally both are suited. It should be noted that greases should only be used sparingly to prevent overheating.

Greases used for lifelong lubrication are preferred. A central lubrication systems that is available can also supply the rotary stroke bearing. Solid lubricants are not suitable for rotary stroke bearings.

Provided that the rotary stroke bearing is not fully loaded up to the load capacity, a dry running is possible because of the high quality of the MarMotion rotary stroke bearings. This means that it can also be used in applications where lubrication is not permitted, e.g. in the food industry, optics, but also in high vacuum or cleanroom applications. Executions made of 1.4112 stainless steel (special design) are recommended for dry run applications. However, a lower load capacity of the rotary stroke bearing has to be taken into account.

MarMotion rotary stroke bearings are preloaded ball bearings, they are thus generally subject to the same laws that apply to other ball bearings. The basic load ratings C10 specified here have been determined with regard to a high-precision guide and do not represent the limits of the load capacity. Provided that the rotary stroke bearing remains absolutely free of contaminations and corrosion, and suitable lubrication is ensured, a virtually unlimited service life can be expected. The most heavily loaded ball zone must not be loaded with more than F10 ≤ C10.

The safety increases to the extent that the load rating C10 is higher than the ball zone that has the highest load of F10.

If the maintenance instructions are observed, the wear of a MarMotion rotary stroke bearing is so low that it can be disregarded. However, if wear still occurs, e.g. in the form of clearly visible running marks on the surfaces, this can be caused by the following:

- The bearing is contaminated with abrasive materials.

- Condensation causes corrosion at the contact points between the ball, shaft and bushing.

- Corrosive media have penetrated the bearing.

- Strong moments, forces or impacts have overloaded the bearing.

Combined with high speed movements, the above-mentioned reasons may lead to a rapid destruction of the running surfaces. In all cases, it must be ensured that all disturbing influences are consistently eradicated.

Cleaning with subsequent greasing as part of the regular maintenance work is beneficial for open or only partially covered rotary stroke bearings. It improves the running properties of the rotary stroke bearing and helps to prolong the service life.